PLDs (Programmable Logic Devices): Flexibility and Power for Modern Electronics

In the world of digital electronics, the ability to customize hardware functionality has revolutionized product development, enabling greater efficiency and adaptability. One key technology that facilitates this customization is Programmable Logic Devices (PLDs). These devices are designed to provide configurable logic that can be tailored for a wide range of applications, from simple logic circuits to complex system-level designs.

This article delves into the principles behind PLDs, their different types, their applications, and the key advantages they bring to industries ranging from telecommunications to automotive engineering.

What Are Programmable Logic Devices (PLDs)?

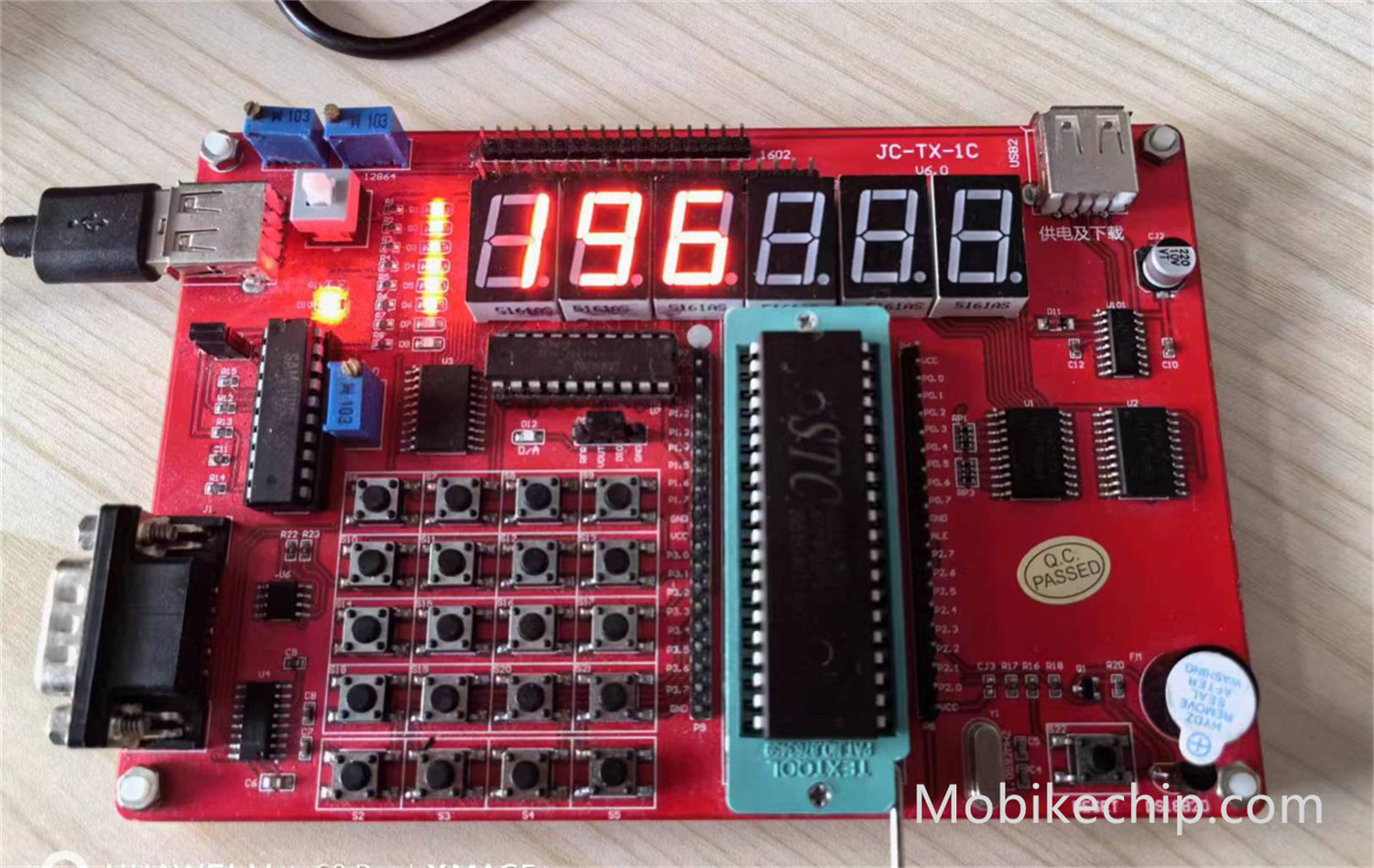

A Programmable Logic Device (PLD) is an integrated circuit that can be programmed to perform a wide range of logic functions. Unlike traditional fixed-function logic circuits, PLDs allow users to define the specific logic behavior they require, making them highly versatile and adaptable.

PLDs are essentially a category of chips that combine hardware flexibility with the simplicity of software-based programming. They consist of an array of programmable gates and interconnections that can be configured to execute specific logic tasks. The configuration of these devices is typically done using a hardware description language (HDL) like VHDL or Verilog, which is then compiled into a bitstream that programs the device.

How Do PLDs Work?

At the core of every PLD is a programmable logic array. The device contains a matrix of logic gates that can be programmed to perform various functions. These logic gates can be connected together to form more complex circuits, enabling the PLD to be configured for a variety of digital tasks.

PLDs are designed to be reprogrammed, meaning they can be altered even after they’ve been deployed in a system. This reconfigurability makes them extremely flexible compared to fixed-function devices like ASICs (Application-Specific Integrated Circuits), which are designed for a single, unchangeable purpose.

The process of programming a PLD typically involves the following steps:

- Design Entry: The designer specifies the desired logic functions using a hardware description language (HDL).

- Synthesis: The HDL code is synthesized into a netlist, which defines how the logic gates and connections are arranged.

- Implementation: The netlist is mapped onto the PLD architecture, creating a configuration file (bitstream) that defines the device’s behavior.

- Programming: The bitstream is loaded into the PLD, programming the device with the desired logic configuration.

Types of PLDs

PLDs come in different types, each with varying levels of complexity and capability. The most common types of PLDs include Simple PLDs (SPLDs), Complex PLDs (CPLDs), and Field-Programmable Gate Arrays (FPGAs). Let’s take a look at each:

Simple PLDs (SPLDs)

Simple PLDs are the most basic form of programmable logic devices. They typically consist of a small number of logic gates and are used to implement simple combinational logic functions such as AND, OR, NOT, and XOR.

SPLDs are ideal for applications where only a few logic functions are required. They are commonly used in situations where custom logic is needed to replace discrete logic components like gates and flip-flops.

- Applications: Custom logic for consumer electronics, small embedded systems, signal processing, and interface circuits.

Complex PLDs (CPLDs)

Complex PLDs are more advanced than SPLDs and offer a greater number of logic gates and more sophisticated interconnection networks. CPLDs are capable of implementing more complex combinational and sequential logic functions, and they support larger designs with more flexibility.

CPLDs are typically used in applications that require a higher level of complexity than SPLDs can offer but don’t need the full capabilities of an FPGA. They can be programmed to implement logic circuits, state machines, and even some limited forms of digital signal processing.

- Applications: Networking, communications systems, data acquisition systems, automotive electronics, and control systems.

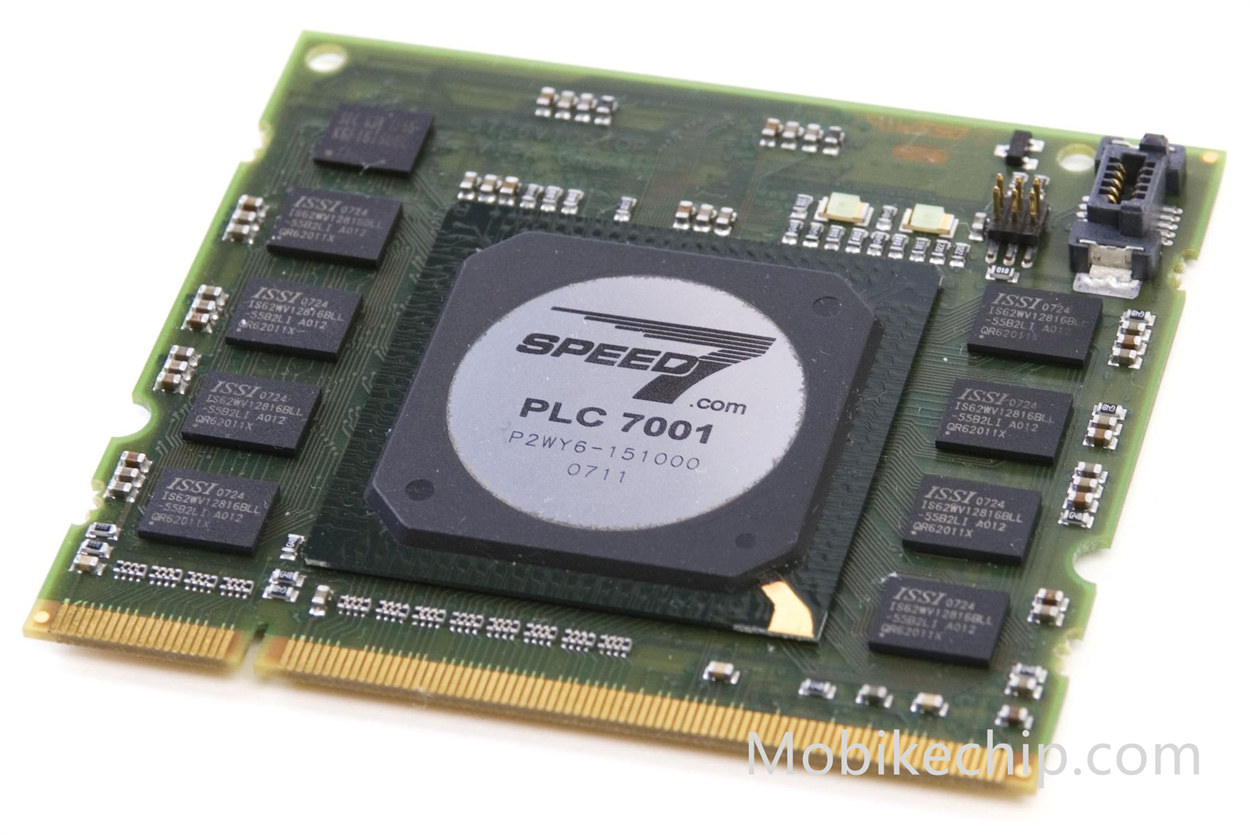

Field-Programmable Gate Arrays (FPGAs)

FPGAs are the most complex and powerful type of PLD. They contain thousands or even millions of programmable logic cells and interconnections, enabling them to handle highly complex tasks and large-scale designs. FPGAs can implement complete systems on a chip (SoCs) and are capable of performing both combinational and sequential logic functions with great speed and flexibility.

FPGAs also often contain specialized hardware blocks such as digital signal processing (DSP) units, memory blocks, and high-speed I/O interfaces. These features allow FPGAs to be used in a wide variety of applications, from telecommunications to scientific computing.

- Applications: Telecommunications, video processing, data centers, signal processing, automotive systems, medical devices, and industrial control systems.

Key Advantages of PLDs

PLDs offer a range of benefits that make them an attractive option for a wide variety of applications:

1. Flexibility and Customization

PLDs allow designers to create customized logic circuits that can be adapted to their specific needs. Unlike fixed-function ICs, PLDs can be reprogrammed to support new features, functions, or protocols as needed. This makes PLDs highly valuable in applications where flexibility and adaptability are key.

2. Faster Time-to-Market

With PLDs, designers can implement custom logic without the need to develop a new ASIC from scratch. This dramatically reduces design time and accelerates time-to-market, allowing companies to bring products to market faster and more cost-effectively.

3. Reduced Component Count

PLDs can replace multiple discrete components (such as logic gates, multiplexers, and flip-flops), reducing the overall component count in a design. This not only saves space on the PCB but also simplifies the design process and improves system reliability.

4. Lower Development Costs

Because PLDs are programmable, they eliminate the need for expensive and time-consuming custom hardware development. For low- to medium-volume production runs, PLDs can be a more cost-effective alternative to ASICs.

5. Prototyping and Rapid Iteration

PLDs are an excellent choice for prototyping new designs or rapidly iterating on a product. If a design change is required, the PLD can be reprogrammed without having to develop new hardware or redesign the PCB. This makes PLDs particularly useful in research, development, and experimental designs.

Applications of PLDs

PLDs have a wide range of applications in various industries. Let’s look at some of the most common uses:

1. Consumer Electronics

PLDs are widely used in consumer electronics for tasks such as custom audio/video processing, power management, and signal routing. They can be programmed to replace traditional discrete components, providing flexibility and efficiency in designs.

- Example: A set-top box may use PLDs to manage signal routing between components or to perform custom video/audio encoding/decoding.

2. Telecommunications and Networking

In telecommunications and networking, PLDs are used to implement custom data protocols, signal processing, and communication interfaces. Their high-speed performance and reconfigurability make them ideal for dynamic environments like 5G networks, Wi-Fi routers, and switching systems.

- Example: PLDs in network switches can be programmed to handle specific traffic patterns or protocols, improving network performance and efficiency.

3. Automotive Systems

In the automotive industry, PLDs are used in a variety of systems, including advanced driver assistance systems (ADAS), engine control modules (ECMs), and in-vehicle communication systems. The ability to customize logic and support complex data processing makes PLDs an essential component of modern automotive electronics.

- Example: A vehicle's collision detection system may use a PLD to process input from sensors and make real-time decisions about braking or steering.

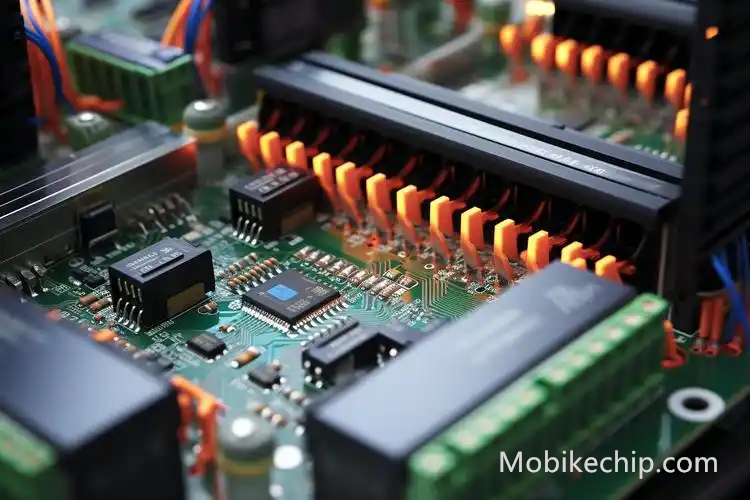

4. Industrial Control and Automation

PLDs are used in industrial control systems for tasks such as motion control, sensors, and data acquisition. Their ability to interface with both analog and digital systems makes them ideal for applications where precise control and real-time decision-making are required.

- Example: In an industrial robot, PLDs can be used to control motor movements and process feedback from position sensors.

Conclusion

Programmable Logic Devices (PLDs) have revolutionized the way we design and implement digital systems. With their flexibility, reconfigurability, and high performance, PLDs offer a powerful solution for industries ranging from telecommunications to automotive and industrial automation. Whether you need a simple logic circuit or a complex, high-speed system, PLDs can provide the customization and performance you need.

At MobikeChip, we offer a wide selection of PLDs from leading manufacturers, ensuring that you have access to the best components for your next design. With our extensive product portfolio and competitive pricing, MobikeChip is your trusted partner for all your electronic component needs.

About Us

MobikeChip offers a broad range of genuine electronic components from over 2,600 manufacturers at competitive prices. Our product portfolio includes Integrated Circuits (ICs), Discrete Semiconductor Products, Resistors, Capacitors, Relays, Switches, Transformers, Sensors, Transducers, Inductors, Coils, Chokes, Potentiometers, Variable Resistors, Crystals, Thermal Management products, and more.

Category page: PLDs (Programmable Logic Device)-Embedded-Manufacturers-Dealer-MobikeChip

Reprinted from: https://www.mobikechip.com/static-blog-detail/178.html

Comments

Post a Comment