How to discharge a capacitor? AC flux capacitor Sample-Buy

Understanding how to discharge capacitors safely and effectively is an essential skill in the operation and maintenance of electronic components. Capacitors, as components that store electrical energy, may still carry a dangerous charge even after the power has been turned off, which can lead to safety accidents if not handled properly. Today, MobikeChip will take you to learn how to discharge capacitors.

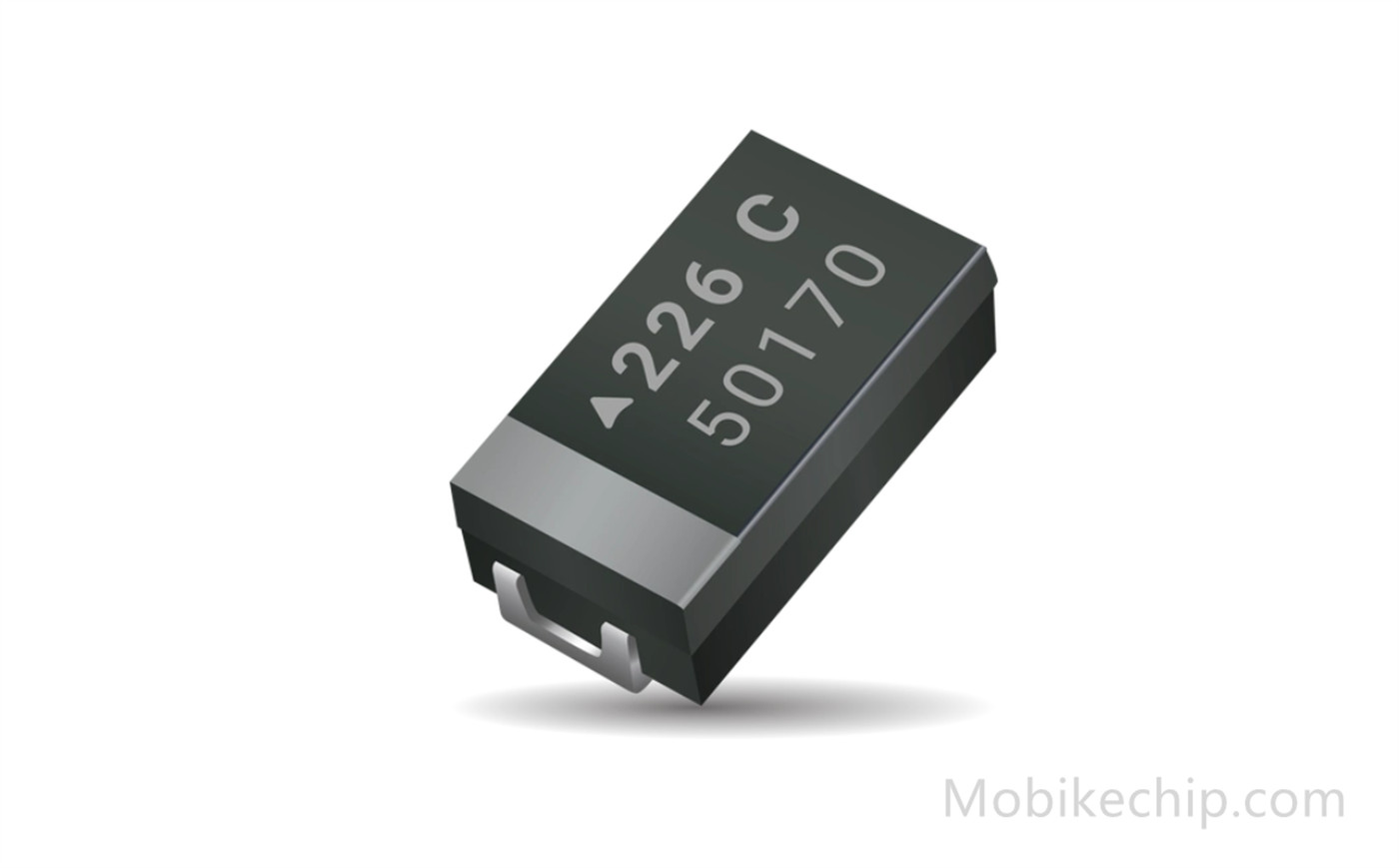

➡️ Capacitor Buy

The need to discharge: to avoid potential risks

Capacitors are widely used in all kinds of electronic equipment, from household appliances to industrial control cabinets, and they store a large amount of electrical energy during operation. When the equipment needs maintenance, replacement of components or debugging, if the capacitor is not discharged, these residual charges may be released inadvertently, causing electric shock injury to the operator, and in serious cases, even life-threatening.

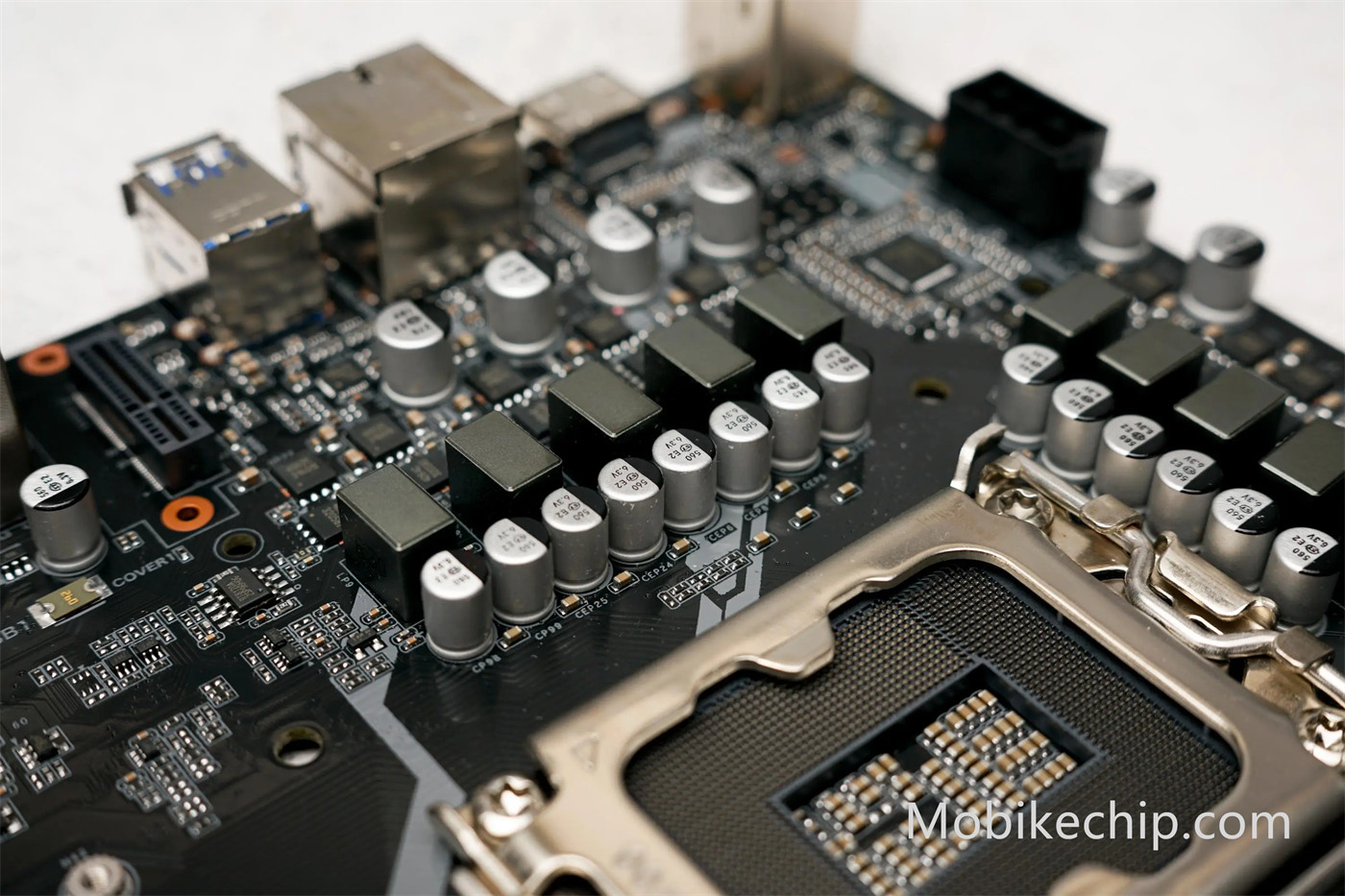

Moreover, when the undischarged capacitor is connected to the new circuit, it may damage other electronic components due to the instantaneous high-current shock, resulting in the failure of the entire circuit. For example, in the computer motherboard repair, if the motherboard is not discharged on the high-capacity electrolytic capacitors, replace the chip or plug the interface, the residual charge triggered by sparks may burn the new chip, so that the repair of the loss of all efforts. Therefore, fully aware of the need to discharge, is to protect personal safety and equipment integrity of the key first step.

Resistance discharge method: simple and practical

Resistance discharge method is one of the most common capacitor discharge method, the operation is relatively simple. First of all, you need to prepare a suitable resistance value of the resistor, in general, for small-capacity capacitors (such as a few microfarads to dozens of microfarads), the choice of a few hundred kilo-ohms to a few megohms of resistance can be; and large-capacity capacitors (hundreds of microfarads and above), the resistance can be in the tens of kilo-ohms or so, in order to ensure that the process of discharging both safe and efficient.

During operation, connect the two ends of the resistor to the poles of the capacitor, taking care that the connection should be firm to avoid poor contact and electric sparks. At this point, the stored electrical energy of the capacitor will be emitted in the form of heat energy through the resistors, which can be observed to be slightly warm. Wait for a certain period of time, usually estimated according to the size of the capacitor's capacity and the resistance value of the selected resistor, which may take only a few seconds to a dozen seconds for small capacitors, and a few minutes for large capacitors, until the voltage at both ends of the capacitor drops to zero or close to zero. This method is inexpensive, easy to follow, and suitable for most everyday electronic repair scenarios.

Short-circuit discharge method: convenient but cautious use

Short-circuit discharge method is a more direct and faster way, as the name suggests, is directly with the conductor will be shorted to the poles of the capacitor, so that the charge is instantly released. However, this method is extremely dangerous, improper operation can easily lead to strong electric sparks or even explosion, so be sure to use caution.

If short-circuit discharge, must ensure that the operating environment is safe, no flammable and explosive substances, the operator needs to wear insulated gloves, goggles and other protective equipment. Using a well-insulated wire or a special short-circuit tool, quickly and briefly touch the poles of the capacitor to release the charge instantly, and then quickly move away from the conductor. Generally only recommended in emergencies, such as capacitor smoke, fire and other dangerous conditions, and the operator has a wealth of experience when used, and try to avoid daily maintenance to prevent accidents.

Specialized equipment discharge: efficient and safe

In some professional electronic laboratories or industrial production scenarios, for high-voltage, large-capacity capacitors, often using specialized discharge equipment. These devices have accurate voltage monitoring, current control functions, in accordance with the preset procedures for safe and efficient discharge of capacitors.

For example, the discharge of high-voltage pulse capacitors in power test equipment requires a specialized pulse discharge device. It can smoothly release the high-voltage charge on the capacitor in a very short time, avoiding the impact on the neighboring circuits and equipment. The operator only needs to set the discharge parameters according to the device's instruction manual, and the discharge process can be completed with one-button startup, which not only guarantees the safety of operation, but also improves the work efficiency and meets the stringent requirements for capacitor discharge in complex electronic systems.

How to check capacitor?

At MobikeChip, we not only provide high-quality capacitor products, but also emphasize on teaching you professional electronic component knowledge and operation skills. Knowing how to discharge capacitors will help you in your journey of repairing and debugging electronic devices. If you encounter problems in capacitor discharge, testing or application, please feel free to visit MobikeChip website, our professional team will be happy to answer your questions.

Comments

Post a Comment