How do current sense transformers work?

Current-sense transformers play a key role in modern power systems and electronic equipment for accurate current monitoring and measurement. Today, MobikeChip will provide you with an in-depth analysis of the working principle of current sensing transformers, and take you to unravel its mystery.

The cornerstone role of the basic principle of electromagnetic induction

(A) Review of electromagnetic induction phenomenon

The work of current induction transformer is based on the important physical principle of electromagnetic induction. When there is a changing current in the conductor, it will produce a changing magnetic field around it, a phenomenon known as the magnetic effect of the current. Conversely, when a closed conductor loop is in a changing magnetic field, the loop will produce an induced electromotive force, which in turn forms an induced current, which is the phenomenon of electromagnetic induction. Current induction transformer is the clever use of this principle, to realize the induction and measurement of current.

(B) in the current induction transformer applications

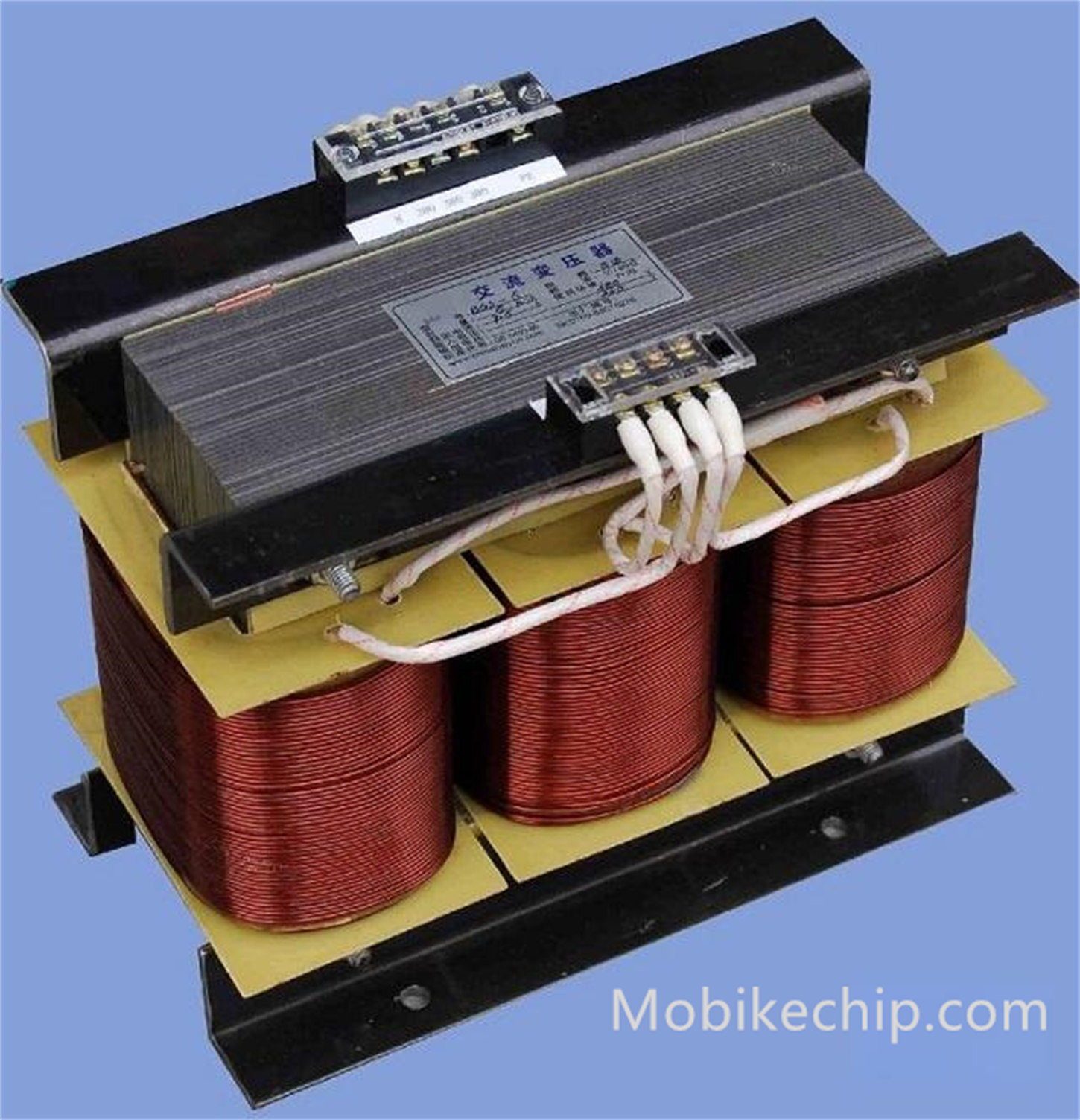

In the current induction transformer, the primary winding passes through the current to be measured. This current produces a magnetic field that varies with the magnitude and direction of the current. This varying magnetic field passes through the core of the transformer and extends to the area where the secondary winding is located. Since the secondary winding is in a varying magnetic field, an induced electromotive force is generated in the secondary winding according to the laws of electromagnetic induction. By measuring the induced electromotive force or induced current in the secondary winding, the size of the current passing through the primary winding can be indirectly known, thus realizing the monitoring of current.

Winding construction and function analysis

(A) The key role of the primary winding

The primary winding is the part of the current induction transformer that is connected to the measured current. Its design and construction have an important impact on the performance of the transformer. Parameters such as the number of turns of the primary winding, the diameter of the wire, and the winding method of the winding determine the sensitivity and accuracy of the transformer for sensing currents of different sizes. For example, for the measurement of large currents, the primary winding with fewer turns and thicker wire diameter is usually used to reduce the resistance of the winding, reduce energy loss, and at the same time ensure that it can accurately sense the magnetic field changes generated by large currents.

(B) Signal output of secondary winding

The secondary winding produces induced electromotive force and induced current under the action of the changing magnetic field generated by the primary winding. The number of turns of the secondary winding is related to the number of turns of the primary winding, and the large current in the primary winding can be converted into small current in the secondary winding through a reasonable turns ratio, which is convenient for subsequent measurement and processing. For example, in a current sensing transformer with a turns ratio of 100:1, if the primary winding passes a current of 100A, the secondary winding will output a current of 1A according to the transformer's converter ratio, which makes it easier to measure accurately with conventional measuring instruments.

Influence of iron core on working performance

(A) The role of magnetic conductivity of the iron core

Iron core is an important part of the current induction transformer, usually made of high permeability materials such as silicon steel sheet. The main role of the core is to provide a low reluctance path for the magnetic field, to enhance the coupling effect between the magnetic field generated by the primary winding and the secondary winding. As the silicon steel sheet has good magnetic conductivity, can guide the magnetic field to focus through, greatly improving the utilization rate of the magnetic field, so that the secondary winding can more effectively sense the primary winding current changes generated by the magnetic field, thus improving the measurement accuracy and sensitivity of the current induction transformer.

(B) reduce hysteresis and eddy current loss

Another important role of the iron core is to reduce hysteresis and eddy current losses. Under the action of the alternating magnetic field, the iron core will produce hysteresis phenomenon, that is, the change of magnetic induction intensity in the iron core lags behind the change of magnetic field strength, which will lead to energy loss. At the same time, the changing magnetic field will also produce eddy currents in the iron core, making the iron core heat up, also resulting in energy loss. Through the use of silicon steel sheet stacked iron core, and coated with an insulating layer on the surface of the silicon steel sheet, can effectively reduce the generation of eddy currents, reduce hysteresis losses, and improve the efficiency of the current induction transformer.

The actual application of the workflow

(A) Current monitoring in the power system

In the power system, the current induction transformer is widely used in current monitoring. For example, in the high-voltage transmission line, by installing a current-sensing transformer, the current size in the line can be monitored in real time. When the current in the line changes, the primary winding of the current-sensing transformer senses the change in current and produces a changing magnetic field, and the secondary winding converts this magnetic field change into an induced current. This induced current is processed and transmitted to monitoring equipment, such as ammeters, power analyzers, etc., through which the operator can learn about the current in the line in real time in order to detect line overloads, short circuits and other faults in a timely manner.

(B) Current measurement in industrial automation

In the field of industrial automation, the current sensing transformer is used to measure the working current of various motors and equipment. For example, in the automated production line of a factory, the normal operation of the motor is crucial to production. By installing a current sensing transformer in the power supply line of the motor, the current of the motor can be monitored in real time. When the motor is overloaded, blocked and other abnormal conditions, the current will change, and the current sensing transformer will convert this change into an electrical signal and transmit it to the control system. Based on the received signal, the control system takes timely protective measures, such as cutting off the power supply, to avoid damage to the motor and to ensure the stable operation of the production line.

At MobikeChip, we are committed to providing you with professional knowledge of electronic components and high quality current sense transformer products. Understanding the working principle of current sense transformer will help you better apply this key component in power monitoring, industrial automation and other fields. If you have any questions about the selection and use of current sense transformer, please feel free to visit MobikeChip website, our professional team will be happy to serve you.

Category page:

https://www.mobikechip.com/static-product-list-detail/10980.html

Comments

Post a Comment